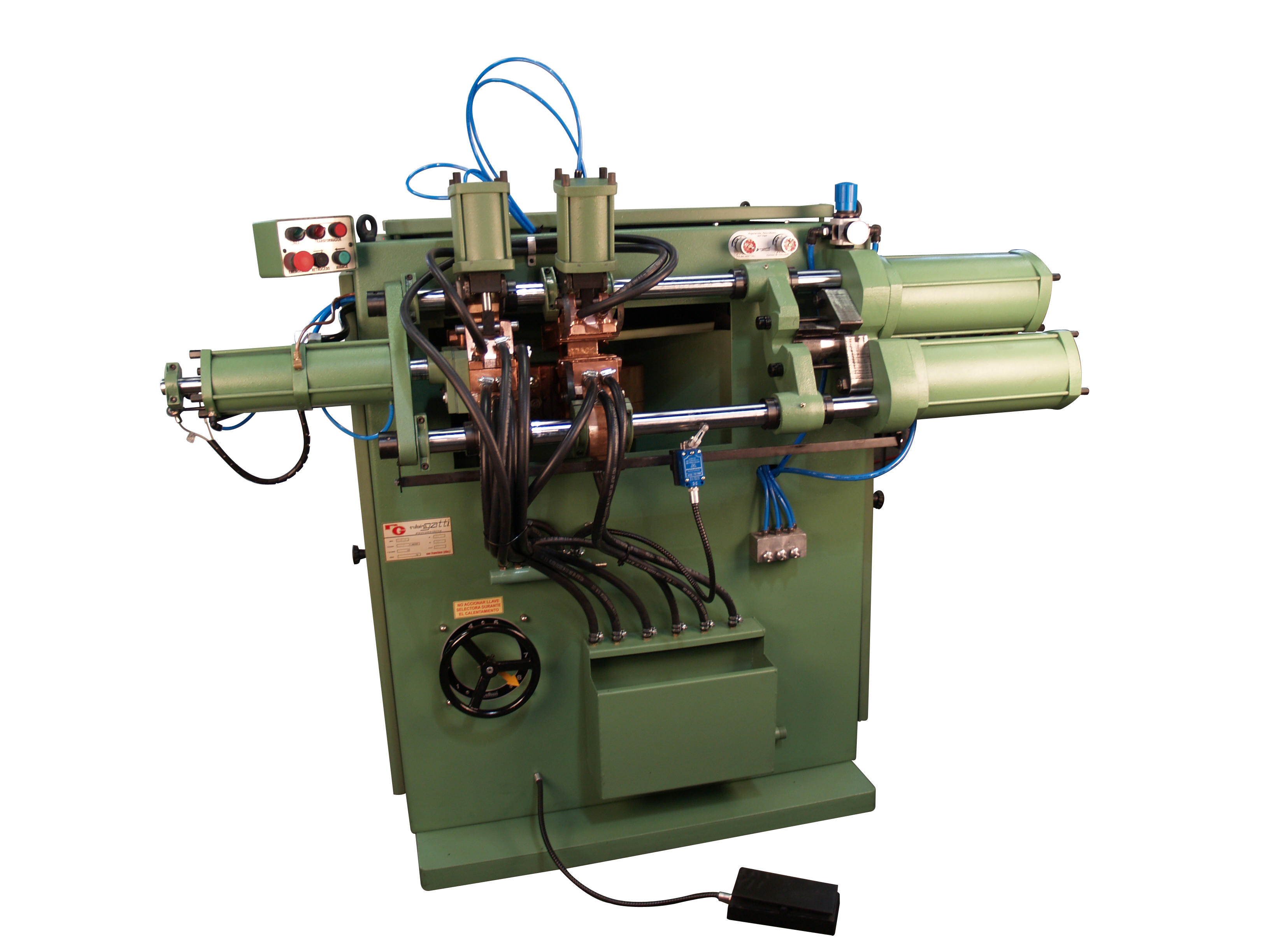

Through-bar electro-forging machine

General Features

This machine is very useful in the elaboration of pieces for pole-line hardware (accessories for electric distribution lines and towers). Used for pre-forging of tension bars, shackles, eyelets, insulator cores, etc. It is constructed of one or two clamps as required to forge at one end only, or in a middle área near one end. The final temperature is adecuate for a back print. They can also be used as bar-warmers.

This machine is very useful in the elaboration of pieces for pole-line hardware (accessories for electric distribution lines and towers). Used for pre-forging of tension bars, shackles, eyelets, insulator cores, etc. It is constructed of one or two clamps as required to forge at one end only, or in a middle área near one end. The final temperature is adecuate for a back print. They can also be used as bar-warmers.

Construction features:

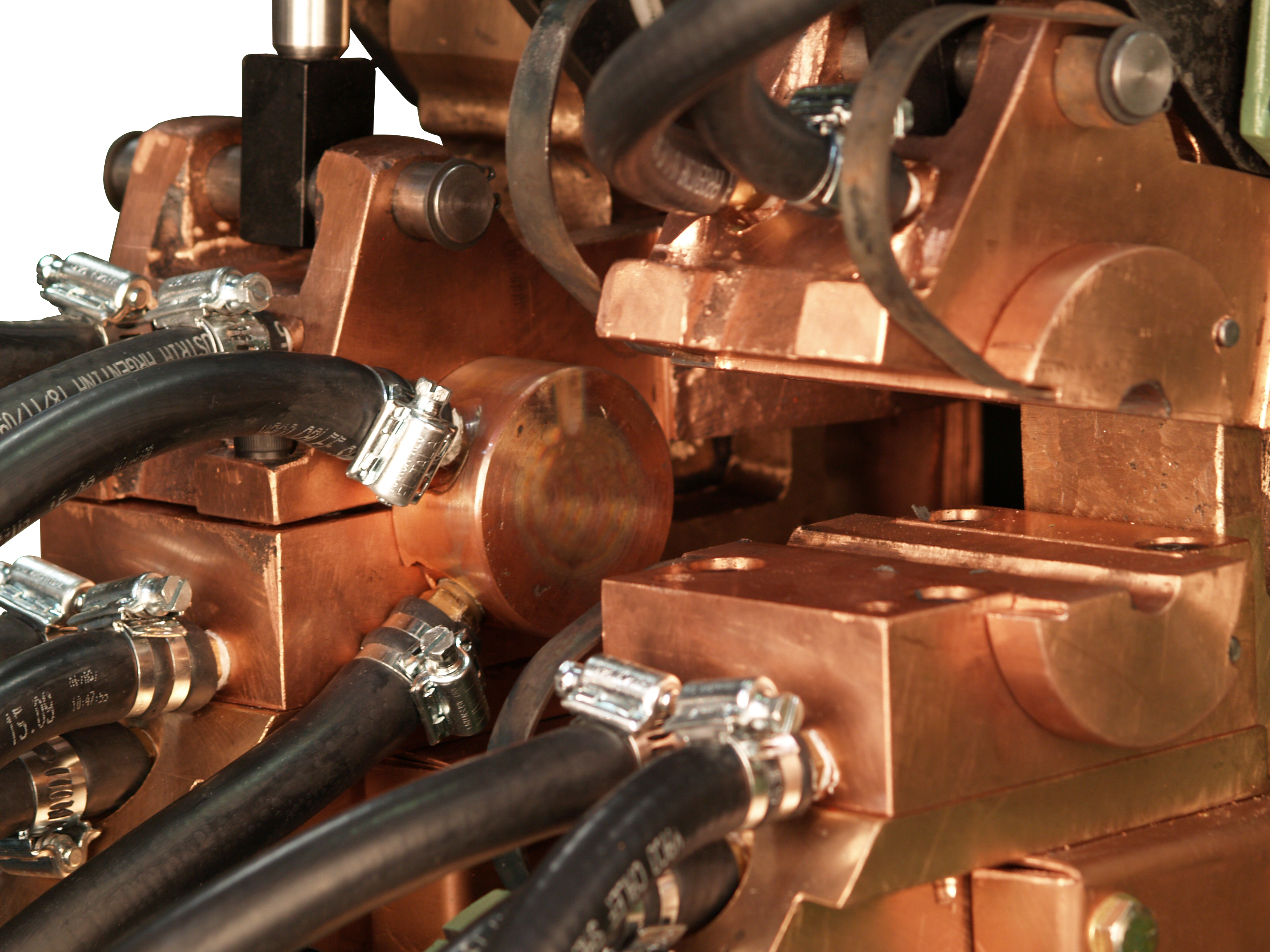

Transformer: fully wound in electrolytic copper, low-loss silicon core, with 8 maximum regulation points, and 8 minimum regulation points (16 points in total). Forced ventilation and watering-cooling for transformers over 70 Kva.

With device for one end of bar with diameter up to 18 mm (through-bar); forged without through-bar 25 mm diameter. With built-in air lung for better pneumatic installation performance. Hydraulically controlled recoil speed and by request can be manufactured with two different speed ranges for some forms needing different speeds.

- MODEL: RNV 40

- POWER TRANSFORMER: Kva 40

- Regulation of the transformer: 8 positions Power high and 8 positions Power low

- Bar diameter to forge: Up to 300 mm mm 10 a 25

- Undefined lengths: mm 10 a 19

- Bar diameter to be heated: mm 10 a 28

- Forging stroke: mm 245

- Max heating capacity: Kg/h 50 a 65

- Dimensions: Length x Height mm 990x2100

- Depth: mm 970